Even laymen are familiar with some methods of cutting into metal. You can use plasma or thermal tools to cut materials into the shapes that you need. Waterjet cutting services are less common but have a distinct utility in manufacturing. Here is a quick guide to what these services are and how they are useful.

Waterjet Cutting Services Use Water to Cut Metal

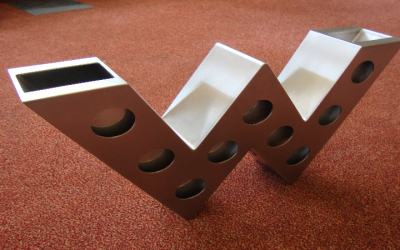

It may seem impossible to cut sheets of metal using water, but that is precisely what waterjet cutting services do. The machine uses a pressurized stream of water mixed with an abrasive, or a garnet, to cut through materials. The water is sprayed out at such high pressure that it can cut through almost any material—you would be surprised at how sturdy this method can be.

Waterjet Tools Are Very Precise

If you choose to work with a company that is highly experienced in waterjet cutting, you will get very good results. This technique is very precise and has minimal margins of error, making it perfect for jobs where there cannot be any deviation from the planned circuit.

Waterjet Cuts Without Heat Distortion

Waterjet cutting is a cold-cutting method. That means that there is no heat applied, only pressure. This is a better choice for materials that are sensitive to high heat, such as aluminium. You don’t have to worry about calibrating the precise temperature to cut without damaging the surrounding material or monitoring the area later for weakness or distortion.