Aluminum plate is a key material in a variety of sectors, prized for its strength, lightweight, and corrosion resistance. Aluminum plates provide outstanding utility and durability in a variety of industries, including aerospace, construction, automotive, and marine. Aluminum plates come in a variety of sizes, thicknesses, and grades, making them suitable for both specialized and high-demand applications. Professional suppliers play an important role in this landscape by offering high-quality, certified materials and ensuring that clients receive the right plates for their applications.

Characteristics and Advantages of Aluminum Plates

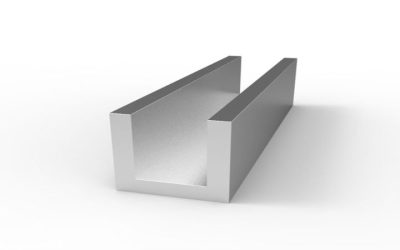

Aluminum plates are popular for a variety of reasons, including their strength and lightweight nature. Aluminum, unlike steel, possesses strength and flexibility, allowing for easy molding or shaping into intricate shapes. This feature makes it particularly valuable in areas like aerospace, where lightweight components are critical for fuel efficiency, and construction, where the combination of durability and ease of installation provides considerable advantages. This feature makes it perfect for outdoor applications, as well as maritime and coastal installations where moisture and salt can damage other metals. Suppliers can provide greater corrosion protection with choices such as anodized or treated plates, extending the longevity of aluminium-based buildings and lowering long-term maintenance costs. Aluminum also has excellent thermal and electrical conductivity. It effectively conducts heat and electricity, making it suitable for applications that require efficient thermal management, such as heat exchangers and cooling systems.

Applications and Importance of Reliable Suppliers

Aluminum plates find their way into a wide variety of applications. Transportation uses aluminum plates for vehicle frames, fuel tanks, and body panels. Aluminum plates are used in construction projects as curtain walls, bridges, and structural reinforcements. Aerospace engineers employ aluminum’s lightweight strength for fuselages, wings, and landing gear components. These industries require customized plate sizes, thicknesses, and grades to meet their unique performance requirements. The importance of reputable aluminum plate suppliers becomes clear when considering the precision required for various applications. Reliable suppliers provide certified materials of consistent quality, ensuring that each plate adheres to exacting industry norms and requirements. In high-risk industries such as aircraft, even little variations in material qualities can jeopardize safety, making quality assurance critical. Companies that source aluminum plates from trustworthy suppliers may be confident that their components will be long-lasting and exceed the required performance criteria. Experienced suppliers may assist clients in determining the best material parameters for a certain project, such as the optimal aluminum grade and thickness. Professional suppliers assist their clients with technical guidance and adaptable inventory solutions, as well as delivering trustworthy materials that meet exact specifications.

The Essential Role of Aluminum Plates in Modern Industry

Aluminum plates continue to play an important part in modern manufacturing, building, and engineering. The material’s unique features, including its lightweight, strength, and corrosion resistance, make it ideal for a wide range of applications. Businesses may acquire high-quality materials that contribute to long-term, efficient, and cost-effective results across a variety of projects by engaging with reputable aluminum plate suppliers. The significance of these suppliers goes beyond basic provision; they provide specialized expertise and personalized solutions that enable industries to innovate and succeed in an ever-changing environment.