One of the difficulties OEMs face, particularly with new concepts and new types of products on the market, is finding production partners to prototype and move into the production of unique design concepts.

A lot of the larger metal fabrication shops are simply not set up to offer custom sheet metal fabrication, which leaves the OEM with the option of changing their design or working with a smaller company that may not have the production capacity needed.

These are not the only two choices if the OEM is willing to consider options. There are companies that not only offer custom sheet metal fabrication, but that also provides high volume production, full quality control throughout the process, as well as very cost-effective rates.

Fabricated to Your Specifications

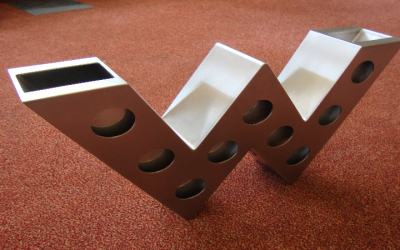

In choosing custom sheet metal fabrication over standard parts and components, the OEM can differentiate their product in the market, improving on performance, duty cycle, efficiency, or any number of other areas.

For specific parts, including HVAC, automotive components, and even construction industry metal fabrication, once the prototype is designed and approved, the actual custom production can be very reasonable in cost. Of course, the higher the volume of the order, the more cost-effective it is to manufacture over the long run.

The choice of custom fabrication can be instrumental in speeding up assembly and manufacturing or building in a secondary parts market for your specific products. Speeding up production lowers total manufacturing costs while adding the secondary parts market helps to boost revenue and increase your product line.